- Home

-

-

Deep hole drilling and boring machine

-

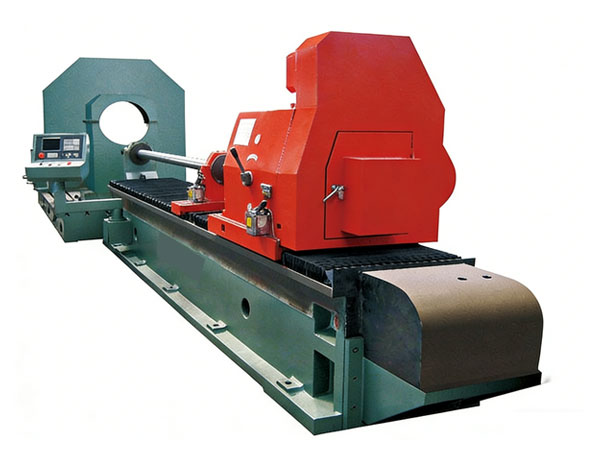

Heavy duty deep hole drilling and boring machine

-

CNC gun drilling machine tool

-

Deep hole powerful honing machine

-

CNC deep hole boring, scraping and rolling machine tool

-

Deep hole boring machine

-

Customized deep hole machine tool

-

Deep hole machining tools

-

deep hole machining

-

- Service

- Contact Us

- Chinese

|

|

|

|

|